The manufacturing industry has come a long way since the first machine was introduced to produce goods. With technological advancements, the industry constantly evolves to keep up with the changing times. Manufacturing is crucial in driving growth and innovation across various sectors in today’s economy. But what does the future hold for this industry?

Understanding the Manufacturing Industry

The production process of various products is vital for different industries, with the manufacturing industry playing a significant role in driving the annual growth rate. Manufacturing businesses cater to wholesalers, distributors, and retailers across industrial, automotive, consumer electronics, chemical, and food and drink manufacturing. Managing production costs is crucial for business owners, making it the first step towards success. As the industry continues to evolve, understanding the nuances of production and commerce becomes the next step for anyone looking to own a manufacturing business.

The Evolution of Manufacturing

In recent years, the manufacturing sector has experienced a transformation due to new technologies. Innovations in machinery have profoundly impacted production processes, while automation and digital marketing have redefined the way manufacturing businesses operate. Niche manufacturing businesses are thriving by incorporating new products and technologies, contributing to the industry’s annual growth rate. In particular, the textile industry has successfully embraced digital transformation, significantly enhancing its production capabilities.

Significance of Manufacturing in Today's Economy

Manufacturing companies play a crucial role in contributing to economic output and market share in today’s economy. They cater to the ever-growing demand for a wide range of products, with small manufacturing businesses meeting more minor quantity needs at retail stores. The sector has seen an influx of innovative manufacturing business ideas, particularly meeting high demand. Moreover, technological advancements have revolutionized manufacturing processes, resulting in increased profitability and growth.

What are Some Future Trends in Digital Manufacturing?

Artificial Intelligence (AI) and Machine Learning (ML) are reshaping the manufacturing landscape and revolutionizing production processes. Meanwhile, Virtual Reality (VR) and Augmented Reality (AR) are driving advancements in product design, enhancing the overall manufacturing experience. These new technologies have significantly boosted the pharmaceutical industry, propelling manufacturing to new heights of efficiency and productivity. The future of digital manufacturing is here, and it’s transforming businesses across various sectors.

Artificial Intelligence Use Cases in Manufacturing

1. Cobots collaborate with humans.

Manufacturers commonly instruct cobots to perform tasks that involve lifting heavy objects or working on factory assembly lines.

2. RPA addresses monotonous tasks.

RPA software can manage high volumes or repetition tasks, facilitate data transfer between systems, execute queries and calculations, and maintain records.

3. Digital twins enhance performance levels.

A digital twin is a virtual representation of a real object that gathers data from its smart sensors. By utilizing AI and other technologies, the digital twin better comprehends the object. Businesses can track an object from start to finish and receive important notifications, like inspection and maintenance alerts.

4. Predictive maintenance enhances safety and reduces expenses.

AI-based predictive maintenance (PdM) can help anticipate servicing needs, improving safety and lowering costs.

5. Lights-out factories result in cost savings.

AI-powered robots can make production lines more accurate, efficient, less tedious, and repetitive.

6. Machine learning algorithms forecast demand.

AI systems that utilize machine learning algorithms can identify purchasing trends in human behavior and provide valuable information to manufacturers.

7. Inventory management prevents bottlenecks from occurring.

AI tools can help manufacturers manage order records and add or delete new inventories.

Artificial Intelligence (AI) and Machine Learning (ML)

Revolutionizing the production landscape, AI and ML technologies are optimizing manufacturing processes. Automation driven by AI is streamlining production, effectively cutting costs. Additionally, machine learning is enhancing demand forecasts, directly impacting business profitability. AI technologies have vastly improved quality control in manufacturing, which is particularly essential in pharmaceutical manufacturing for ensuring product safety. Integrating AI and ML undoubtedly reshapes manufacturing, marking a significant leap toward efficiency and innovation.

Virtual Reality (VR) and Augmented Reality (AR)

Reshaping the way products are designed in manufacturing, VR and AR technologies have become integral. VR is utilized for product prototyping and elevating product quality, while AR optimizes assembly line processes and enhances efficiency. Machinery manufacturing has witnessed a surge in innovation driven by VR tech, leading to amplified production output. Additionally, VR and AR have revolutionized digital marketing for manufacturing businesses, opening new avenues for customer engagement and product showcasing.

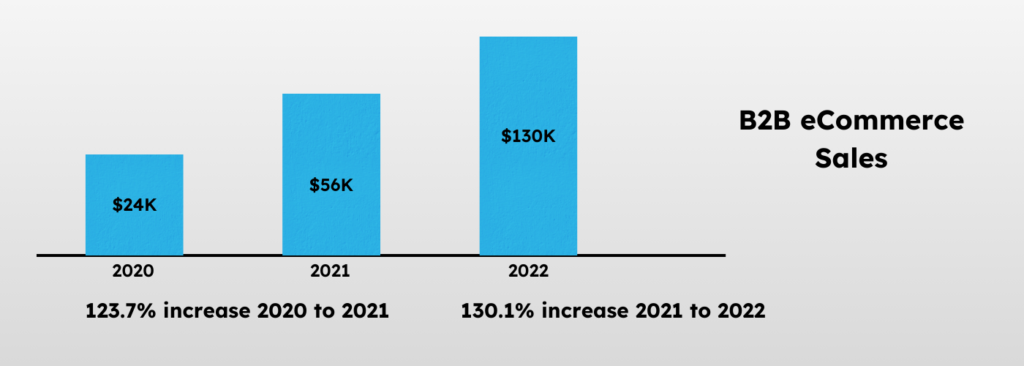

eCommerce and Digital Marketing

In today’s business landscape, digital marketing has become vital for engaging customers and expanding reach. ECommerce platforms allow manufacturers to sell directly to consumers, creating new revenue streams. Leveraging social media and online advertising provides targeted marketing avenues for brand promotion. Gartner reports that 77% of B2B buyers characterize their most recent purchase as intricate or challenging. Utilizing data analytics to track customer behavior can enhance marketing strategies, helping manufacturers stay competitive in the evolving market. Embracing digital marketing and eCommerce is the next step for manufacturers to ensure sustained competitiveness.

Impact of Digital Transformation on Manufacturing Businesses

Innovations driven by digital transformation have enhanced quality control in manufacturing, optimized inventory management to reduce production costs, and connected businesses to potential customers through social media marketing. E-commerce has also expanded the market reach for manufacturing companies. Embracing the right people, place, products, and business ideas drives profitability, marking a significant step toward the future of manufacturing businesses.

Improved Efficiency and Productivity

In today’s manufacturing landscape, digital technologies have revolutionized mass production, enhancing efficiency and productivity. Manufacturers leverage forecasts to increase production output, while automation has streamlined assembly line processes, boosting overall efficiency. Technology has facilitated demand forecasts and optimized production processes, and e-commerce has expanded market reach, driving profitable business growth. These advancements empower manufacturing businesses to operate with unparalleled efficiency, meet increased demand, and drive sustainable growth.

Enhanced Quality Control

Digital transformation has revolutionized real-time quality control monitoring in today’s manufacturing landscape. Innovative technologies are now utilized to uphold product quality, and automation in quality control has significantly minimized production errors, ensuring sustained profitability. Digital specifications have played a pivotal role in elevating product quality across diverse manufacturing sectors, including pharmaceuticals, guaranteeing product safety. These advancements underscore the critical importance of quality control in driving business growth and customer confidence.

Supply Chain Optimization

Digital technologies have revolutionized supply chain management in the manufacturing industry. Manufacturers employ digital procurement to streamline supply chain processes and enhance efficiency. Advanced inventory management systems have significantly improved the effectiveness of supply chain operations. Additionally, ecommerce has simplified direct shipping, leading to increased profitability within the supply chain. Furthermore, digital forecasts optimize demand management, further boosting the efficiency of the supply chain.

Preparing Your Manufacturing Business for Digital Transformation

Embracing digital technologies can significantly enhance production, streamline operations, and boost profitability for manufacturing businesses. Digitizing manufacturing processes reduces production costs and time-to-market while implementing digital inventory management systems optimizes supply chain operations and reduces waste. Utilizing digital marketing strategies allows reaching potential customers and expanding market share. Leveraging social media keeps businesses connected with customers and industry trends, paving the way for successful digital transformation.

Understanding the Need for Change

Recognizing the economic potential of digital transformation in manufacturing is crucial for business owners. The surging demand for digital manufacturing technologies signifies a new phase in the industry’s evolution. Understanding these technologies’ significance and impact on profitability is the first step towards embracing change. Assessing the potential of digital technologies to drive growth and profitability becomes the next natural step for manufacturers. Embracing this evolution is essential for staying competitive in the rapidly changing manufacturing landscape.

Investing in Right Technologies

Investing in the latest technologies enhances manufacturing processes, cuts costs, and elevates product quality. Identifying the right talent and tools drives digital transformation in manufacturing. Digital technologies support the growth and profitability of small manufacturing businesses. Exploring digital manufacturing technologies improves production, quality control, and profitability. Embracing new technologies is crucial for driving profitability, business growth, and market share in the manufacturing sector.

Conclusion

In conclusion, the manufacturing industry is undergoing a massive transformation driven by digital innovations. The integration of technologies like Artificial Intelligence (AI), Machine Learning (ML), Virtual Reality (VR), Augmented Reality (AR), eCommerce, and Digital Marketing is revolutionizing the way businesses operate. These advancements are improving efficiency and productivity, enhancing quality control, and optimizing the supply chain. Manufacturing businesses must embrace digital transformation to stay competitive. This involves understanding the need for change and investing in the right technologies. By doing so, companies can position themselves for success and thrive. So, do not wait any longer. Start preparing your manufacturing business for the digital revolution today.

Other Articles You May Be Interested In